Dacromet coating is a product workpiece produced by Dacromet technology. Dacromet is also called zinc chromium film coating. It has high corrosion resistance and is currently in its infancy. It is a high-tech cleaning Production process technology, it is a new leap of epoch-making significance in the surface treatment industry.

This process can replace electrogalvanizing, cadmium, zinc-based alloy, hot-dip galvanizing, hot-spray galvanizing and mechanical galvanizing of steel parts. Its main advantages are:

1. High corrosion resistance: Dacromet metal coated products can withstand smoke for 600-1200 hours, which is 7-10 times higher than electro-galvanized;

2. No hydrogen embrittlement: the coating process does not produce hydrogen embrittlement, and is suitable for surface anticorrosion treatment of high-strength bolts and Dacromet coated parts;

3. High weather resistance: adapt to various climate changes and cold and heat changes, used for sun-exposed parts and water-immersed parts;

4. High heat resistance: the heat resistance temperature can reach 300 degrees Celsius, which is suitable for high-strength components of automobile and motorcycle engines;

5, Cleanliness, Dacromet coated parts do not need pickling, no harmful gas and liquid discharge, it is a clean production process.

Dacromet coated parts processing products have been widely used in various industries such as automobiles, motorcycles, building components, bridges, electric power, highway guardrails, etc.

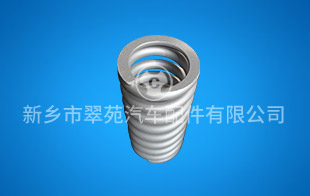

Dacromet coated parts

Product Details

Previous:Dacromet Coated Pads